Wiring Your Model Train Layout Quickly and Easily

The Power Pack

Model trains run on a low DC voltage. This DC voltage is created by the power pack which takes the AC voltage from your wall socket and converts it to 12 to 15 volts direct current (DC).

Direct current is directional so when applied to your track will drive your locomotive in one direction, and when the polarity is reversed on the track it will go in the opposite direction. Changing direction is done by changing the position of the direction switch on your power pack.

By varying the voltage supplied to the tracks, this will vary the speed the locomotive travels at. Varying the voltage is done by adjusting the dial on your power pack.

12 to 15 volts DC is not dangerous but is always advisable to unplug the power pack when you work on the electrics of your model train layout.

The exception to this is if you have Lionel or Marklin equipment. They are identified with their 3 rail track which uses a low AC (Alternating Current) voltage. The operation of the power pack is the same as DC.

All power packs are not equal. Sizes vary, starting with the power pack that comes with a model train starter kit. This power pack is basically only powerful enough to drive one train around a small oval.

The larger power packs will drive multiple trains running at once with accessories such as lighting and working machinery. Some power packs come with remote throttles. This allows you to move around your layout while controlling the speed of your train.

Meters are available on some power packs to show how much current is being drawn while others have more accessory facilities to drive lights and other equipment.

More expensive power packs will provide a smooth start motion for your locomotive and then gently increase the locomotive speed, just like a real train.

The cheaper power packs tend to be frustrating as it’s usually one extreme or the other. The locomotive doesn’t move and when it does it takes off at a hundred miles per hour.

The bigger power packs have more safety features built in to protect from accidental short circuits and overheating… you definitely get what you pay for.

As your layout grows you will want more than one power pack. It is a good idea to separate the power packs that drive your locomotives from the one that drives your accessories.

High electrical resistance on your track, due to dirty track or loose rail joiners, will reduce the voltage supplied to your locomotive when it passes that point which will result in the locomotive slowing down or even stopping.

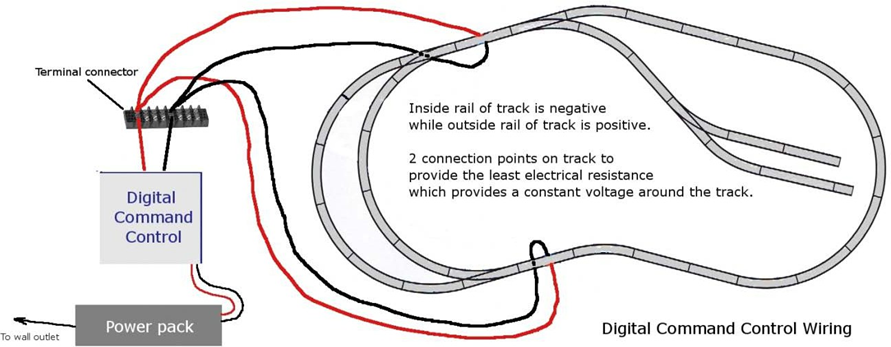

To reduce the possibility of this happening, it is a good idea to have multiple connection points on your track. This reduces the electrical resistance and the voltage drop that causes locomotives to lose power as they get further away from the power pack.

A good quality power pack will just about last forever, if treated right. It is important to operate the power pack within its limits, unplug it when it’s not in use and operate it in a dry environment.

If your power pack starts overheating, giving off a burning odor, expels smoke, makes a buzzing noise, the circuit breaker keeps tripping or the cord is damaged, then switch it off and have it checked by an electrician.

Power packs can cause fires if they overheat, so don’t take any chances.

Wiring Model Train Tracks

As we’ve explained, a power pack will provide a direct current to the track. This polarizes the rails, making the inside rail positive, and the outside rail negative, in one train direction.

By changing the direction switch or dial of the power pack, the positive rail now becomes negative, and the negative rail becomes positive, which changes the direction of the train.

The standard way of wiring model railroads is to have the positive on the right hand rail when the locomotive is going forward.

This electrical system is simple when applied to an oval track, or oval within an oval layout operating 1 train.

Start adding turnouts so the train can pass through a loop and enter the main line in the other direction and you have to make electrical adjustments to avoid a short circuit and potentially burning out your power supply.

The answer to this problem is to create isolated electrical sections with separate power packs. Toggle switches are then used to toggle between the power packs.

The same solution is used to operate more than 1 train but this can be very confusing for beginners, and could easily result in a short circuit with a burnt out power pack… an expensive mistake!

DCC (Digital Command Control) has eliminated this problem.

With DCC it’s as simple as applying a constant voltage to the entire track.

The locomotives are fitted with digital receivers which ignores the track voltage until the digital command control sends a signal to the locomotive’s unique address.

The locomotive will then do what it is told from the digital command control.

Figure 47

Because all the locomotives have their own unique address, many locomotives can be operated on one layout with one power pack and much less of a short circuit danger.